Yav dhau los Moulds ua thiab cov khoom pub dawb tsim

Yas Txhaj Moulding Parts - Tsim & Ntau lawm rau koj xav tau

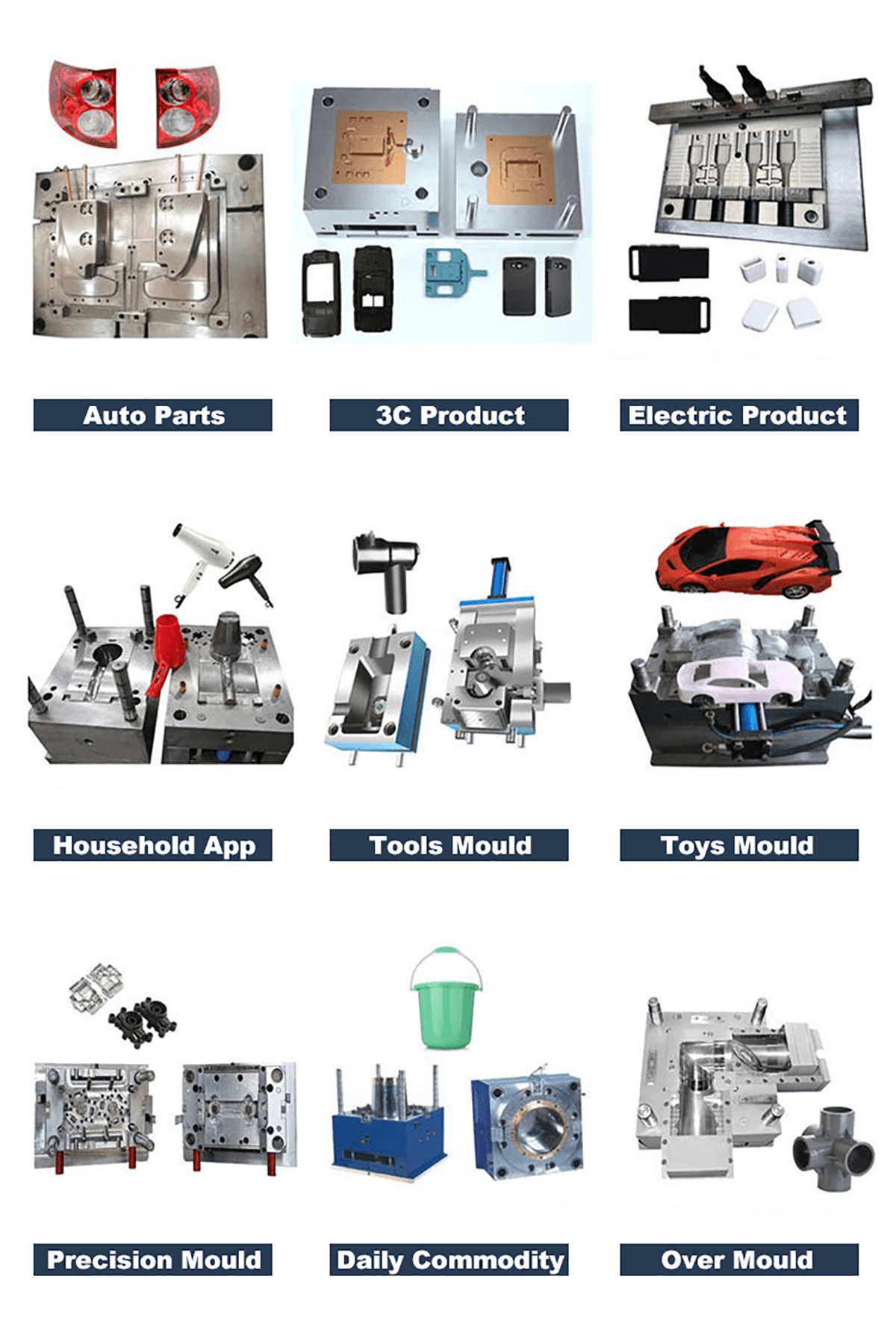

Hauv peb lub tuam txhab, peb txaus siab rau peb tus kheej ntawm kev muab kev pabcuam thawj zaug hauv kev txhaj tshuaj yas molded qhov chaw tsim khoom.Nrog peb cov high-precision tsim pwm thiab txiav-ntug txhaj tshuaj molding tshuab, peb muaj peev xwm ua loj tsim cov khoom yas nrog yooj yim.Peb pab neeg ntawm cov kws tshaj lij engineers tau mob siab rau kev tsim khoom raws sijhawm ntawm kev ua haujlwm siab yas txhaj tshuaj molded qhov chaw.Nrog cov kev paub dhau los, peb tau ua tiav cov pwm tsim rau ntau yam lag luam, suav nrog cov khoom siv hauv tsev, cov khoom ua si, 3C cov khoom siv hluav taws xob, cov khoom siv pib thiab cov khoom siv niaj hnub, thiab lwm yam. Tsis tas li ntawd, peb lub peev xwm ntau lawm txhua hli ua rau peb tsim tau 200 pawg ntawm cov pwm precision thiab txhaj 200,000. -500,000 daim ntawm cov khoom yas.

Thaum raug txhaj tshuaj molded qhov chaw, precision thiab zoo yog qhov tseem ceeb tshaj plaws.Nkag siab txog qhov tseem ceeb ntawm cov xwm txheej no, peb lub tuam txhabinvests nyob rau hauv qhov tseeb technology thiab machinerylos xyuas kom meej tias peb xa cov khoom raws li peb cov neeg siv khoom xav tau.

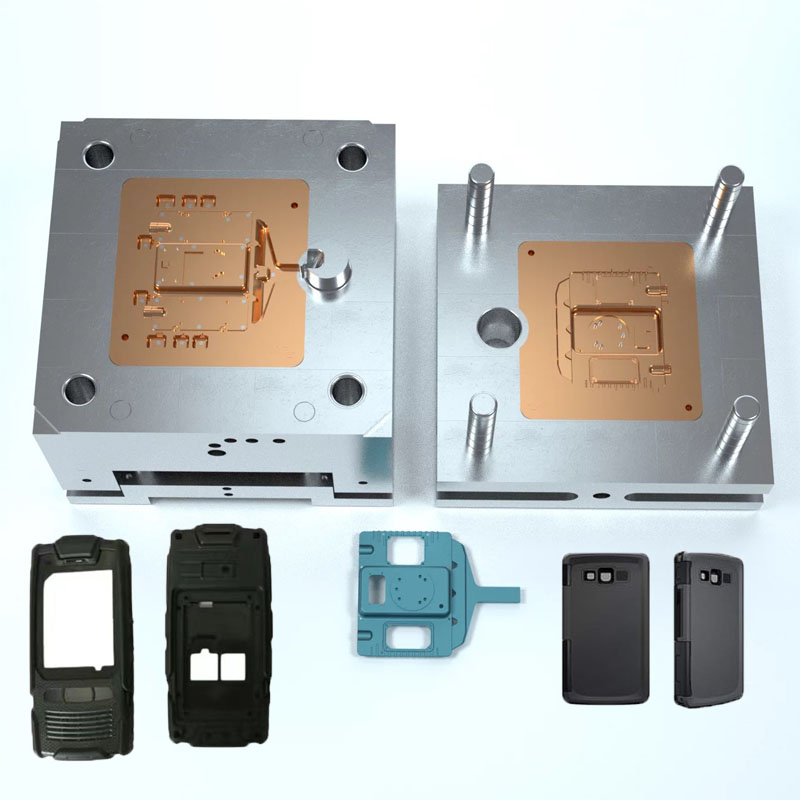

Ib qho ntawm peb lub zog yog nyob rau hauv high precision pwm peb tsim.Cov pwm no ua lub luag haujlwm tseem ceeb hauv cov txheej txheem txhaj tshuaj molding raws li lawv txiav txim siab qhov kawg cov duab thiab qhov zoo ntawm qhov.Peb cov engineers tau paub txog kev kos duab ntawm kev tsim pwm, kom ntseeg tau tias txhua lub pwm yog ua tib zoo tsim thiab tsim kom tau raws li peb cov neeg siv khoom specifications.Txawm hais tias nws yog ib qho yooj yim los yog tsim qauv, peb pab neeg muaj kev txawj ntse los tsim pwm uas tsim cov khoom yas zoo.

Ntxiv nrog rau peb cov kws tshaj lij hauv kev tsim pwm, peb tau nqis peev hauv lub xeev-of-the-art txhaj tshuaj molding tshuab.Cov tshuab no tau nruab nrog cov yam ntxwv siab heev uas tso cai rau peb tsim cov khoom yas zoo dua thiab raug.Nrog kev pab los ntawm cov tshuab no, peb tuaj yeem ua tiav cov txiaj ntsig zoo ib yam, kom ntseeg tau tias txhua qhov ua tau raws li cov qauv xav tau.Tsis tas li ntawd, peb cov txheej txheem txhaj tshuaj molding yog automated, txo qhov kev pheej hmoo ntawm kev ua yuam kev thiab txo lub sijhawm ntau lawm.

Peb lub tuam txhab ua haujlwm rau ntau yam kev lag luam, suav nrog cov khoom siv hauv tsev, cov khoom ua si, 3C cov khoom siv hluav taws xob, cov khoom siv pib thiab cov khoom siv niaj hnub.Peb qhov kev paubhauv cov kev lag luam no muab rau peb nkag siab tob txog lawv cov kev xav tau tshwj xeeb.Qhov kev paub no ua rau peb muab cov kev cai daws teeb meem uas ua tau raws li peb cov neeg siv khoom xav tau tshwj xeeb.Txawm hais tias nws yog qhov kev tsim khoom me me lossis ib qhov project loj, peb tau cog lus tias yuav xa cov khoom txhaj tshuaj molded zoo tshaj qhov kev cia siab.

Thaum ua haujlwm nrog cov neeg siv khoom, peb ua qhov tseem ceeb ntawm kev sib txuas lus thiab kev nkag siab.Los ntawm kev sib tham thawj zaug mus rau qhov kawg ntawm kev xa khoom, peb ua haujlwm ze nrog peb cov neeg siv khoom kom ntseeg tau tias lawv tau ua tiav.Peb pab pawg engineers thiab cov kws tshaj lij nyob ntawm tes los daws cov teeb meem lossis cov lus nug uas yuav tshwm sim.Peb ntseeg tias kev sib txuas lus zoo yog tus yuam sij rau kev sib koom tes ua tiav thiab peb siv zog los tsim kev sib raug zoo nrog peb cov neeg siv khoom.

Hais txog lub peev xwm ntau lawm, peb muaj peev xwm tuav cov haujlwm loj.Nrog lub peev xwm ntau lawm ntawm 200 teeb tsa cov pwm pwm hauv ib hlis thiab muaj peev xwm txhaj pwm 200,000-500,000 yas qhov chaw, peb tuaj yeem ua tau raws li lub sijhawm xa khoom nruj yam tsis muaj kev cuam tshuam zoo.Peb cov txheej txheem tsim khoom tau zoo thiab kev ua haujlwm tau zoo tso cai rau peb txhawm rau txhim kho cov khoom lag luam thiab xyuas kom peb cov neeg siv khoom tau txais lawv cov xaj raws sijhawm.

Nyob rau hauv xaus, peb lub tuam txhab yog ib tug trustworthy tsum ntawm high-zoo txhaj molded qhov chaw.Nrog peb cov high-precision tsim pwm thiab txiav-ntug txhaj tshuaj molding tshuab, peb muaj peev xwm ua loj tsim cov khoom yas nrog yooj yim.Peb cov kev paub dhau los, kev txawj ntse thiab kev cog lus rau qhov zoo ua rau peb xaiv thawj zaug hauv kev lag luam xws li cov khoom siv hauv tsev, cov khoom ua si, 3C electronics, nws pib qhov chaw thiab cov khoom siv txhua hnub.Yog li txawm tias koj xav tau kev tsim khoom me me lossis qhov project loj, peb pab neeg tau npaj kom xa cov txiaj ntsig zoo.

Product Detail

| Qhov Chaw Keeb Kwm | Tuam Tshoj |

| Hom Lub Npe | HSLD / Customized |

| Hloov hom | Ntxuam Yas Txhaj Pwm |

| Khoom siv | CNC, EDM txiav tawm tshuab, Yas Machinery, thiab lwm yam |

| Khoom siv | Hlau: AP20/718/738/NAK80/S136 Yas: ABS / PP / PS / PE / PVC / PA6 / PA66 / POM |

| Pwm Lub Neej | 300000 ~ 500000 txhaj tshuaj |

| Tus khiav | Kub khiav los yog txias khiav |

| Hom rooj vag | Ntug/Pin point/Sub/Side Gate |

| Kev kho saum npoo | Matte, Polished, Daim iav polished, kev ntxhib los mos, painting, thiab lwm yam. |

| Pwm Cavity | Ib leeg lossis ntau kab noj hniav |

| Ua siab ntev | 0.01mm-0.02 hli |

| Txhaj Tshuab | 80T-1200 T |

| Ua siab ntev | ± 0.01 hli |

| Dawb qauv | muaj |

| Qhov zoo | one stop solution/free design |

| Daim ntawv thov teb | Cov khoom siv hluav taws xob, cov khoom zoo nkauj, cov khoom siv kho mob, cov khoom siv hauv tsev, Cov khoom siv pib, thiab lwm yam |

Yas Txhaj Moulding: Ib qho kev hloov pauv hauv B-End Sectors

Taw qhia

Yas txhaj tshuaj molding muaj tiag tiag revolutionized manufacturing txheej txheem nyob rau hauv ntau yam B-End industries, qhib lub sijhawm kawg rau innovation thiab kev vam meej.Hauv tsab xov xwm no txhawb nqa, peb yuav nkag siab mus rau hauv lub ntiaj teb loj thiab zoo siab ntawm cov yas txhaj tshuaj molding hauv kev tsim tsheb, khoom siv hluav taws xob, kev lag luam ntim khoom, thiab kev kho mob.Los ntawm kev nthuav tawm cov qauv ntawm lub neej tiag tiag thiab txhawb nqa lawv nrog cov ntaub ntawv txhawb siab, peb yuav pleev xim rau daim duab tiag tiag ntawm qhov txheej txheem ntau yam no tau hloov pauv zoo kawg thiab txhim kho cov haujlwm no.

Yas Txhaj Molding hauv Automotive Manufacturing

Kev lag luam automotive muaj lub koob npe nrov rau kev tsim kho tshiab thiab txhim kho tas li.Los ntawm lub xeev-ntawm-lub-kos duab xyaw mus rau advanced kev nyab xeeb nta, manufacturers yeej ib txwm nrhiav kev los txhim kho lub tsheb kev ua tau zoo thiab zoo nkauj.Ib txoj kev hloov pauv uas hloov pauv kev ua si ntawm kev tsim tsheb yog cov yas txhaj tshuaj molding.

Kev siv cov txheej txheem no, cov tuam txhab tau pom cov sij hawm tsim khoom tseem ceeb ntawm 25% thiab txo cov khoom pov tseg los ntawm 30% piv rau cov txheej txheem ib txwm siv, raws li Society of Automotive Technology qhia.Cov kev txheeb cais tseem ceeb no qhia txog qhov cuam tshuam ntawm kev txhaj tshuaj yas molding.Tsis tsuas yog nws tau hloov pauv kev tsim khoom ntawm cov khoom sib sib zog nqus xws li dashboards, bumpers thiab grilles, tab sis nws kuj tau pab cov neeg tsim tsheb kom ua tiav cov duab zoo dua thiab cov ntsiab lus uas tuaj yeem pab txhim kho roj efficiency.

Yas txhaj tshuaj molding yog cov txheej txheem tsim khoom uas txhaj cov yas molten rau hauv pwm kab noj hniav.Thaum txias thiab solidified, cov yas yog ejected los ntawm pwm los tsim ib tug meej thiab ruaj khov kawg khoom.Cov txheej txheem muaj ntau yam zoo dua li cov txheej txheem tsim khoom.

Ua ntej thiab foremost, yas txhaj tshuaj molding ua rau nws yooj yim los tsim complex qhov chaw.Siv computer-aided design (CAD) software, automotive designers tuaj yeem tsim 3D qauv ntawm cov khoom xav tau.Cov qauv no yog tom qab ntawd hloov mus rau hauv pwm, kom ntseeg tau tias txhua qhov ua tau zoo ib txwm raug thiab zoo ib yam.

Tsis tas li ntawd, kev siv ntawmautomotive yas txhaj tshuaj moldingenables lub teeb yuag Cheebtsam tsis cuam tshuam lub zog thiab durability.Qhov no txhim kho roj efficiency, txij li cov tsheb sib zog yuav tsum tau siv zog tsawg zog.Tsis tas li ntawd, lub teeb yuag ntawm cov khoom molded no pab txhawb rau kev ua haujlwm ntawm lub tsheb tag nrho, nrog rau kev txhim kho kev tuav thiab kev ncua luv luv.

Lwm qhov tseem ceeb ntawm cov yas txhaj tshuaj molding hauv kev tsim tsheb yog nws lub peev xwm los txo cov khoom pov tseg.Tsis zoo li cov txheej txheem ib txwm muaj, uas feem ntau koom nrog kev txiav thiab molding ntau dhau ntawm cov khoom, yas txhaj tshuaj molding xyuas kom cov khib nyiab tsawg.Tsis tas li ntawd, kev muaj peev xwm rov qab siv cov yas seem los ntawm cov pwm yav dhau los ntxiv rau qhov tseem ceeb ntawm cov txheej txheem.

Los ntawm kev siv cov yas txhaj tshuaj molding, automakers tau ncav cuag qhov siab tshiab ntawm kev muaj tswv yim, kev ua tau zoo thiab kev ruaj khov.Txoj kev tsim kho tshiab no tsis yog hloov pauv txoj hauv kev tsim cov khoom siv tsheb, tab sis kuj muab cov neeg tsim qauv muaj kev ywj pheej los tshawb nrhiav cov duab tshiab thiab cov ntsiab lus.Qhov tshwm sim yog pom cov tsheb uas txaus siab rau cov neeg siv khoom thaum pab txhawb rau yav tom ntej ntsuab.

Hauv kev xaus, yas txhaj tshuaj molding tau hloov pauv kev lag luam automotive.Nws lub peev xwm los tsim cov complex, sib sib zog nqus qhov chaw nrog exceptional zoo thiab nthuav dav tau tsav kev lag luam rau pem hauv ntej.Qhov no tsis tsuas yog ua rau kev txuag nqi tseem ceeb thiab txo cov khoom pov tseg, tab sis nws kuj pab txhim kho roj efficiency thiab tag nrho lub tsheb ua haujlwm.Los ntawm cov yas txhaj tshuaj molding, automakers tuaj yeem txuas ntxiv mus thawb cov ciam teb ntawm kev tsim kho tshiab los tsim cov tsheb uas tsis tsuas yog ua tau raws li cov neeg siv khoom xav tau tab sis kuj pab txhawb rau lub neej yav tom ntej.

Txhaj Moulding hauv Consumer Electronics: Hloov Kev Lag Luam

Cov khoom siv hluav taws xob tau dhau los ua ib feem tseem ceeb ntawm peb lub neej, nrog cov smartphones, laptops thiab cov khoom siv hauv tsev ua lub luag haujlwm tseem ceeb hauv kev txhim kho peb lub neej txhua hnub.Hauv qab qhov xwm txheej, cov txheej txheem tsim khoom zoo kawg nkaus hu ua yas txhaj tshuaj molding tau ua lub luag haujlwm tseem ceeb hauv kev hloov pauv cov neeg siv khoom siv hluav taws xob, ua kom muaj kev tsim khoom loj ntawm cov khoom sib txuas thiab tsav tsheb tshiab hauv kev lag luam loj hlob no.

Yas txhaj tshuaj molding tau hloov pauv cov txheej txheem tsim khoom ntawm cov neeg siv khoom siv hluav taws xob, tso cai rau cov tuam txhab tsim cov qauv tsim thiab cov qauv uas yav dhau los tsis tuaj yeem ua tiav.Ib qho chaw tshwj xeeb uas cov yas txhaj tshuaj molding tau muaj kev cuam tshuam loj yog qhov hluav taws xob yas molding.Cov txheej txheem cuam tshuam nrog kev txhaj tshuaj molten yas rau hauv cov pwm kev cai los tsim cov yas tsis muaj seamless thiab ruaj khov rau cov khoom siv hluav taws xob.

Ua tsaug rau qhov kev pom deb, cov neeg tsim khoom tau ua tiav qhov kev txuag nyiaj ntau txog 35% hauv cov nqi tsim khoom (qhov chaw: Electronic Manufacturers Association).Los ntawm kev ua kom yooj yim ntawm cov txheej txheem tsim khoom thiab tshem tawm qhov xav tau rau ntau qhov chaw thiab cov rooj sib txoos, cov yas txhaj tshuaj molding tsis tsuas yog txo lub sijhawm tsim khoom, tab sis kuj ua rau kev ua tau zoo tag nrho ntawm cov txheej txheem tsim khoom.Yog li ntawd, cov tuam txhab lag luam hauv kev lag luam khoom siv hluav taws xob tau ntsib cov khoom lag luam sai dua thiab txhim kho cov txiaj ntsig zoo.

Peb lub tuam txhab yog ibOEM / ODMchaw tsim tshuaj paus tus neeg muag khoom tshwj xeeb hauv cov yas txhaj tshuaj pwm rau cov neeg siv khoom siv hluav taws xob.Nrog peb cov pwm raug xa tawm mus rau ntau tshaj 20 lub teb chaws, peb tau txais kev paub dav dav hauv kev ua kom tau raws li qhov tshwj xeeb ntawm kev lag luam sib txawv.Peb txaus siab rau peb cov pwm tsim thiab tsim cov peev txheej, kom ntseeg tau tias peb cov neeg tau txais cov pwm zoo thiab txhim khu kev qha.

Hauv cov neeg siv khoom siv hluav taws xob, kev zoo nkauj thiab kev tsim qauv ua lub luag haujlwm tseem ceeb.Yas yog ib qho khoom siv tau yooj yim heev uas tuaj yeem sib xyaw ua ke ntawm kev ua haujlwm tshiab thiab tus qauv tsim.Lub peev xwm los sim nrog ntau yam ntaub ntawv xws li polycarbonate (PC) ua rau txoj hauv kev rau cov khoom siv hluav taws xob muaj zog thiab pom kev zoo.PC txhaj tshuaj molding yog ib qho subtype ntawm yas txhaj tshuaj molding uas tuaj yeem tsim cov khoom nrog cov khoom siv zoo heev, ua haujlwm kub kub thiab qhov pom tseeb zoo heev.Qhov no tau tsa lub bar hauv cov neeg siv khoom siv hluav taws xob, muab cov neeg siv nrog cov khoom siv uas tsis tsuas yog ua tau zoo heev, tab sis kuj zoo nkauj thiab sophisticated hauv kev tsim.

Yas txhaj moldingtau thawb cov neeg siv khoom siv hluav taws xob mus rau hauv thaj tsam ntawm qhov tsis muaj qhov kawg.Seamlessness thiab efficiency ntawm cov txheej txheem tsim khoom no tso cai rau cov tuam txhab ua kom tau raws li qhov xav tau hloov pauv ntawm cov neeg siv khoom siv thev naus laus zis.Los ntawm cov xov tooj smartphones nrog bezel-tsawg cov lus qhia rau lub laptops nrog ultra-nyias daim ntawv yam tseem ceeb, yas txhaj tshuaj molding tau nyob rau hauv pem hauv ntej ntawm kev tsim cov cuab yeej uas tsis yog tsuas yog technologically advanced tab sis visually stunning.

Hauv kev xaus, yas txhaj tshuaj molding tau hloov pauv cov neeg siv khoom siv hluav taws xob.Nrog lub peev xwm los tsim cov khoom sib txuas sai dua thiab tus nqi qis dua, cov tuam ntxhab tau txais cov txheej txheem no los coj cov cuab yeej txiav tawm mus rau kev ua lag luam.Los ntawm kev sib txuas cov qauv tsim tshiab nrog cov ntaub ntawv muaj zog xws li polycarbonate, yas txhaj tshuaj molding tau tuaj yeem tsim cov khoom siv hluav taws xob zoo nkauj thiab ntxim nyiam.Ua tsaug rau cov txheej txheem tsim tau zoo no, lub neej yav tom ntej ntawm cov neeg siv khoom siv hluav taws xob zoo li ci ntsa iab dua li yav dhau los, nrog rau ntau yam ntawm cov khoom siv tshiab thiab pom tau zoo xav kom txaus siab rau cov neeg nyiam siv tshuab thoob ntiaj teb.

Yas Txhaj Moulding hauv Kev Lag Luam Ntim

Kev lag luam ntim khoom, paub txog nws txoj kev muaj tswv yim thiab kev tsim kho tshiab, tau dhau los ua kev rov ua dua tshiab nrog rau kev nthuav tawm ntawm cov yas txhaj tshuaj molding.Los ntawm kev siv cov thev naus laus zis tshiab no, cov tuam txhab lag luam tuaj yeem txo lawv cov nuj nqis ntau lawm los ntawm 40% (qhov chaw: Lub Koom Haum Cov Kws Tshaj Lij Tshaj Tawm).

Yas txhaj tshuaj molding tau hloov pauv txoj kev ntim cov kev daws teeb meem tsim, tshwj xeeb nrog cov pwm preform, PET preform pwm, yas hau pwm thiab preform tshuab molding.Cov pwm no tseem ceeb heev rau kev tsim cov khoom ntim ntau yam nrog rau lub raj mis, ntim thiab kaw.

Qhov ntau yam ntawm cov yas txhaj tshuaj molding tuaj yeem tsim cov kev daws teeb meem zoo nkauj uas tsis tsuas yog ua kom cov khoom muaj kev nyab xeeb thiab siv tau ntev, tab sis kuj nyiam cov neeg siv khoom nrog qhov muag pom cov ntsiab lus.Los ntawm kev siv preform pwm, manufacturers muaj peev xwm tsim seamless thiab txaus nyiam fwj thiab ntim.PET preform pwm tshwj xeeb tsim cov pob tshab thiab ruaj khov ntim cov kev daws teeb meem dav siv hauv kev lag luam dej haus thiab zaub mov.

Tsis tas li ntawd, cov yas hau pwm tuaj yeem tsim kom muaj kev ruaj ntseg thiab xau-pov thawj kaw rau lub raj mis thiab ntim.Cov hau no tsis tsuas yog tiv thaiv cov ntsiab lus ntawm lub pob, tab sis kuj muab kev yooj yim thiab yooj yim ntawm kev siv rau cov neeg siv khoom.Qhov tseeb thiab kev ua haujlwm ntawm cov yas txhaj tshuaj molding ua kom txhua lub hau ua tau zoo ib yam, ua rau muaj kev txhim khu kev lag luam ntim.

Tsis tas li ntawd, preform tshuab moulding tau dhau los ua cov txheej txheem nrov hauv kev lag luam ntim.Cov txheej txheem yuav tsum tau txhaj cov khoom siv yas rhuab rau hauv pwm, uas tom qab ntawd nthuav dav nrog cov cua compressed los tsim cov khoom ntim ntim.Preform tshuab moulding muaj qhov tshwj xeeb tsim qauv yooj yim, ua rau cov tuam txhab tsim cov duab tshwj xeeb thiab ntau thiab tsawg rau lawv cov kev daws teeb meem.Qhov no tsis tsuas yog txhim kho kev zoo nkauj ntawm cov khoom, tab sis kuj txhim kho cov neeg siv khoom.Lub teeb yuag tsis tau ruaj khov, cov tshuab molded ntim cov kev daws teeb meem no muab kev yooj yim thiab txav tau yooj yim rau cov neeg siv khoom thaum txo cov nqi xa khoom rau cov tuam txhab.

Yas txhaj tshuaj moulding paves txoj hauv kev rau kev ntim cov kev daws teeb meem uas siv cov khoom siv rov ua dua tshiab.Kev lag luam tab tom hloov mus rau cov ntaub ntawv zoo ib puag ncig xws li bioplastics, uas tau muab los ntawm cov peev txheej txuas dua tshiab thiab tuaj yeem siv tau yooj yim.Los ntawm kev siv cov yas txhaj tshuaj molding, manufacturers muaj peev xwm txo lawv cov kev cuam tshuam ib puag ncig thaum muab cov kev daws teeb meem tshiab.

Cov tuam txhab hauv kev lag luam ntim tau lees paub qhov txiaj ntsig zoo ntawm cov yas txhaj tshuaj molding thiab muab tso rau hauv lawv cov txheej txheem tsim khoom.Cov tuam txhab no siv preform pwm, PET preform pwm, yas hau pwm, thiab preform tshuab moulding thev naus laus zis los tsim cov khoom lag luam zoo, tus nqi tsim nyog thiab kev ntim khoom ruaj khov.

Tag nrho cov nyob rau hauv tag nrho cov, yas txhaj molding tau coj cov kev hloov loj rau lub ntim kev lag luam.Los ntawm kev siv cov pwm preform, PET preform pwm, yas hau pwm, thiab preform tshuab moulding technologies, manufacturers tau muaj peev xwm tsim cov ntim ntim cov ntsiab lus uas ua kom cov khoom muaj kev ruaj ntseg, ntev, thiab cov neeg siv khoom txaus siab.Tsis tas li ntawd, kev txhaj tshuaj yas molding pab txhawb kev txhim kho kev ntim khoom kom ruaj khov, pab txo qis kev lag luam ib puag ncig.Nrog nws cov versatility thiab nqi-zoo, yas txhaj molding tseem yog tus tsav tsheb shaping lub neej yav tom ntej ntawm kev lag luam ntim.

Yas Txhaj Molding hauv Kev Kho Mob: Revolutionizing Patient Safety and Well-being in Healthcare

Cov txheej txheem tsim khoom raug thiab txhim khu kev qha yog qhov tseem ceeb los ua kom cov neeg mob muaj kev nyab xeeb thiab kev noj qab haus huv tag nrho.Txhua yam khoom siv kho mob siv los ntawm cov kws kho mob yuav tsum ua raws li cov qauv nruj rau kev ua tau zoo, kev ua kom zoo thiab ua kom tsis muaj menyuam.Txhawm rau ua tiav cov hom phiaj no, kev qhia txog kev txhaj tshuaj yas molding yog qhov tsis muaj kev xav txog kev hloov pauv.Cov txheej txheem tsim khoom no tau hloov pauv kev lag luam kev noj qab haus huv los ntawm kev tso cai rau cov tuam txhab xa cov khoom siv kho mob zoo.Cov kws kho mob tau pom qhov kev txhim kho loj heev hauv kev tsim khoom ua tsaug rau cov yas txhaj tshuaj molding.Raws li Medical Manufacturing Association, cov txheej txheem no ua rau muaj qhov tseem ceeb 50% txo cov khoom tsis xws luag (qhov chaw: Medical Manufacturing Association).

Qhov kev lees paub zoo tshaj plaws no yog qhov tseem ceeb thaum tsim khoom siv kho mob tseem ceeb xws li koob txhaj tshuaj, catheters thiab cov cuab yeej phais.Los ntawm kev txo qis qhov tsis xws luag, cov neeg mob thiab cov kws kho mob tuaj yeem tso siab rau cov khoom no nrog kev ntseeg siab paub tias lawv cov haujlwm thiab kev nyab xeeb yog qhov tseem ceeb tshaj plaws.Ib qho ntawm cov txiaj ntsig tseem ceeb ntawm kev txhaj tshuaj yas molding yog lub peev xwm los xyuas kom tsis muaj menyuam ntawm cov khoom kho mob.Hauv qhov chaw kho mob, kev pheej hmoo kis mob yog qhov kev txhawj xeeb loj.Txawm li cas los xij, nrog cov yas txhaj tshuaj molding, manufacturers tuaj yeem tsim cov khoom siv kho mob tsis muaj menyuam ncaj qha los ntawm pwm.Qhov no tshem tawm qhov xav tau ntawm kev ua kom tsis muaj menyuam ntxiv, txo qhov muaj peev xwm kis tau tus mob thiab txhim kho kev saib xyuas neeg mob.Los ntawm kev txo qis kev pheej hmoo kis tus kab mob, cov chaw kho mob tuaj yeem muab qhov chaw nyab xeeb rau cov neeg mob, thaum kawg txhawb lawv txoj kev rov zoo thiab kev noj qab haus huv.

Tsis tas li ntawd, kev txhaj tshuaj yas molding ua rau qhov tseeb thiab ua tau zoo ntawm cov khoom siv kho mob nyuaj.Lub versatility ntawm no manufacturing txheej txheem enables tsim complex designs, xyuas kom meej cov khoom kho mob sib sau ua ke seamlessly thiab ua flawlessly.Txawm hais tias nws yog cov cuab yeej phais nyuaj lossis cov koob txhaj tshuaj raug ntsuas, cov yas txhaj tshuaj molding ua rau cov tuam txhab ua tau raws li qhov xav tau ntawm kev lag luam kho mob.

Qhov kev ua tau zoo thiab kev ua tau zoo no tsis tsuas yog muaj txiaj ntsig zoo rau cov neeg mob, nws kuj tseem pab txuag cov nqi rau cov kws kho mob thiab ua rau kev saib xyuas zoo dua rau cov pej xeem.Qhov cuam tshuam ntawm kev txhaj tshuaj yas molding ntawm kev kho mob txuas mus deb dhau ntawm kev tsim khoom nws tus kheej.Los ntawm kev siv cov thev naus laus zis thev naus laus zis no, kev lag luam kho mob thoob ntiaj teb tau nce qib ntawm kev ua tau zoo.Raws li qhov tseeb thiab kev ntseeg tau dhau los ua tus qauv, tag nrho cov khoom kho mob zoo dua qub, ua rau cov neeg mob tau txais txiaj ntsig zoo dua.Los ntawm kev txo cov kev pheej hmoo ntawm kev kis kab mob kom txo qis cov khoom tsis xws luag, kev txhaj tshuaj yas yas ua lub luag haujlwm tseem ceeb hauv kev cawm neeg txoj sia thiab txhim kho tag nrho cov qauv ntawm kev saib xyuas neeg mob.Raws li kev lag luam kho mob txuas ntxiv mus ntxiv, yog li xav tau cov khoom kho mob uas muaj tseeb, txhim khu kev qha.Yas txhaj tshuaj molding ncaj qha hais txog cov kev xav tau no, muab cov tuam txhab tsim cov cuab yeej lawv xav tau kom xa cov khoom tshwj xeeb thiab tsis muaj menyuam.Lub zog hloov pauv ntawm cov txheej txheem tsim khoom no tso cai rau cov kws kho mob tsom mus rau qhov tseem ceeb tshaj plaws: kev noj qab haus huv thiab kev noj qab haus huv ntawm lawv cov neeg mob.

Hauv kev xaus, yas txhaj tshuaj molding tau dhau los ua kev hloov pauv hauv kev kho mob kev tsim khoom.Nws ua rau kev tsim cov khoom lag luam zoo, meej thiab tsis muaj menyuam, txo qhov kev pheej hmoo ntawm kev kis kab mob thiab txhim kho kev saib xyuas neeg mob.Los ntawm cov txheej txheem ntawm kev hloov pauv no, kev lag luam kev noj qab haus huv thoob ntiaj teb tau cawm tib neeg txoj sia thiab tsa lub bar ntawm kev ua tau zoo.Nrog rau qhov kev xav tau loj zuj zus ntxiv rau cov neeg mob tau txais txiaj ntsig zoo dua, kev txhaj tshuaj yas molding yuav tsis muaj qhov xav tau ua lub luag haujlwm tseem ceeb hauv kev tsim kho lub neej yav tom ntej ntawm kev tsim kho kev noj qab haus huv.

Xaus

Yas txhaj tshuaj molding tau coj nyob rau hauv ib tug era ntawm boundless lub sij hawm thiab transformative innovation nyob rau hauv B-End industries.Los ntawm kev nthuav tawm cov qauv hauv ntiaj teb tiag tiag thiab txhawb nqa lawv nrog cov ntaub ntawv tsis txaus ntseeg, peb tau pom qhov cuam tshuam zoo ntawm cov txheej txheem no hauv kev tsim tsheb, cov neeg siv khoom siv hluav taws xob, kev lag luam ntim khoom, thiab kev kho mob.Kev txuag nqi, kev tsim kho kom zoo dua qub, thiab txhim kho cov khoom tsim tau los ntawm cov yas txhaj tshuaj molding tau hloov pauv cov haujlwm no, tawm hauv qhov tsis txaus ntseeg ntawm lawv txoj kev vam meej thiab kev loj hlob.Raws li peb lees paub qhov tsis muaj peev xwm ntawm cov yas txhaj tshuaj molding, peb pom lub neej yav tom ntej ci ntsa iab uas tsis muaj qhov kawg rau kev tsim khoom zoo tshaj plaws thiab cov neeg siv khoom txaus siab.

Yog li, cia peb pib taug kev zoo kawg li no, qhov chaw muaj tswv yim, kev ua tau zoo, thiab kev ruaj ntseg sib tsoo los ntawm qhov nruab nrab muaj zog ntawm cov yas txhaj tshuaj molding.Ua ke, peb tuaj yeem tsim lub ntiaj teb uas kev tsim kho tshiab paub tsis muaj kev cia siab, thiab txhua qhov kev lag luam vam meej nrog kev pab los ntawm cov thev naus laus zis zoo kawg no.

Xav tias dawb rautiv taujpebthaum twg los tau!Peb nyob ntawm no los pab thiab xav hnov los ntawm koj.

Lub Hoobkas Paub meej

Ntau Moulds

Kev xa khoom

Kev ntim tshwj xeeb rau koj: rooj ntoo nrog zaj duab xis

1. Txhawm rau kom zoo dua kev nyab xeeb ntawm koj cov khoom, kev tshaj lij.

2. Zoo rau ib puag ncig, kev pabcuam ntim khoom yooj yim thiab ua haujlwm tau zoo.

FAQ

HSLD: Yog lawm, feem ntau cov khoom seem rau tuag casting pwm peb muaj pwm ntxig, pwm ncej, qhov rais tub ntxhais, txav tub ntxhais, lub taub hau ntawm nozzle.Koj tuaj yeem tshawb xyuas thiab qhia txog yam khoom seem uas koj xav tau.

HSLD: Peb cov pwm ntxig yog ua los ntawm DAC.

HSLD: Peb lub hauv paus txav yog ua los ntawm FDAC.

HSLD: Yog.

HSLD: Cov khoom sib txawv muaj qhov sib txawv, feem ntau ntawm 0.01-0.02mm