I. Kev Taw Qhia

Kev lag luam automotive tau ntev lawm nyob rau hauv pem hauv ntej ntawm technology innovation thiab manufacturing zoo.Ib qho ntawm cov ntaub ntawv tseem ceeb uas tau hloov pauv kev lag luam no yog yas.Cov khoom yas tam sim no yog ib qho tseem ceeb rau kev tsim, kev ua tau zoo, thiab kev ua kom zoo ntawm cov tsheb niaj hnub.Tsab ntawv xov xwm no yog txhawm rau tshawb nrhiav lub luag haujlwm tseem ceeb ntawm cov yas txhaj tshuaj molding hauv kev ua kom tau raws li kev lag luam automotive kev xav tau rau precision, durability, thiab raug nqi tsim khoom.

A. Cov ntsiab lus luv luv ntawm Automotive Industry's Reliance on Plastic Components

Yas Cheebtsam tau dhau los ua ntau yam hauv kev lag luam tsheb, nrhiav kev siv hauv txhua yam los ntawm sab hauv trim mus rau sab nrauv lub cev.Lawv muab cov khoom siv sib sib zog nqus rau cov khoom siv ib txwm siv, txhim kho roj efficiency thiab txo cov pa phem.Tsis tas li ntawd, plastics muab kev tsim qauv yooj yim, tso cai rau kev tsim cov duab nyuaj thiab kev sib xyaw ua ke uas txhim kho kev zoo nkauj thiab kev ua haujlwm.

B. Qhov tseem ceeb ntawm kev ua haujlwm zoo thiab kev ua haujlwm siab hauv kev tsim tsheb

Kev ua tau zoo thiab kev ua tau zoo yog qhov tseem ceeb hauv kev tsim tsheb.Cov neeg tsim khoom yuav tsum xyuas kom meej tias cov tsheb ua tau raws li cov qauv kev nyab xeeb thiab kev ua tau zoo thaum tseem muaj nqi sib tw.Cov txheej txheem tsim khoom zoo yog qhov tseem ceeb rau kev ua tiav cov hom phiaj no, thiab kev txhaj tshuaj yas yas sawv tawm raws li cov txheej txheem uas xa tawm ntawm ob sab.

C. Thesis Statement

Yas txhaj moldingyog qhov kev daws teeb meem tseem ceeb rau kev ua tau raws li kev lag luam automotive xav tau.Nws muaj kev sib xyaw ua ke ntawm qhov tseeb, kev tsim qauv yooj yim, kev xaiv cov khoom siv, thiab cov nqi-zoo uas tsis sib xws los ntawm lwm txoj kev tsim khoom.

II.Nkag siab txog Automotive Industry's Needs

Txhawm rau kom txaus siab rau lub luag haujlwm ntawm cov yas txhaj tshuaj molding, nws yog ib qho tseem ceeb kom nkag siab txog cov kev xav tau tshwj xeeb ntawm kev lag luam tsheb.

A. Txheej txheem cej luam ntawm ntau haiv neeg ntawm cov khoom siv yas siv hauv cov tsheb niaj hnub

Cov tsheb niaj hnub siv ntau cov khoom siv yas, los ntawm cov fasteners me me thiab cov khoom txuas mus rau lub cev loj thiab cov khoom siv.Cov khoom no yuav tsum ua kom tau raws li cov qauv tsim nyog rau lub zog, ruaj khov, thiab tiv thaiv ib puag ncig xws li kub, txias, thiab UV hluav taws xob.

B. Hais txog qhov yuav tsum tau muaj rau Precision, Durability, thiab tus nqi-zoo

Precision yog qhov tseem ceeb hauv kev tsim tsheb tsim khoom kom ntseeg tau tias cov khoom sib haum ua ke seamlessly thiab ua haujlwm raws li qhov xav tau.Durability yog qhov tseem ceeb sib npaug, raws li cov khoom yuav tsum tiv taus qhov nruj ntawm kev siv txhua hnub thiab kev sim ntawm lub sijhawm.Tus nqi-kev ua tau zoo yog qhov tseem ceeb hauv kev lag luam uas cov paj tau nruj thiab kev sib tw hnyav.

C. Cov ntaub ntawv tshawb fawb qhia txog qhov tseem ceeb ntawm cov khoom yas hauv Automotive tsim thiab ua haujlwm

Cov ntaub ntawv tshawb fawb txog kev ua tiav ntawm cov khoom siv yas hauv kev tsim tsheb tuaj yeem muab cov kev nkag siab zoo.Piv txwv li, kev siv cov yas hauv cov khoom siv cav tuaj yeem ua rau txo qhov hnyav thiab txhim kho kev ua haujlwm.Ib yam li ntawd, kev sib koom ua ke ntawm cov yas hauv lub tsheb sab hauv tuaj yeem txhim kho kev nplij siab thiab kev zoo nkauj.

III.Qhov zoo ntawm Kev Txhaj Tshuaj Molding

Yas txhaj moldingmuaj ntau yam zoo uas ua rau nws yog qhov kev xaiv zoo tshaj plaws rau kev tsim tsheb.

A. Precision thiab sib npaug

Txhaj tshuaj molding ua kom nruj tolerances thiab uniformity nyob rau hauv automotive qhov chaw.Qhov kev txiav txim siab no tau ua tiav los ntawm kev siv cov txheej txheem tswj tau zoo thiab lub xeev-of-the-art machinery, uas tuaj yeem tsim cov khoom nrog qhov tseeb.

B. Tsim Flexibility

Ib qho ntawm cov yam ntxwv ntawm kev txhaj tshuaj molding yog nws cov qauv tsim yooj yim.Nws tso cai rau cov tuam txhab tsim cov geometries nyuaj thiab sib koom ua ke ntau yam kev ua haujlwm rau hauv ib qho kev tivthaiv, ua kom cov khoom tsim tawm thiab txo lub sijhawm sib dhos.

C. Kev xaiv khoom

Qhov ntau ntawm cov resins muaj rau kev txhaj tshuaj molding txhais tau hais tias cov tuam ntxhab tuaj yeem xaiv cov ntaub ntawv uas ua tau raws li cov kev cai tshwj xeeb ntawm kev siv tsheb sib txawv.Qhov no suav nrog cov ntaub ntawv sib txawv ntawm lub zog, yoog raws, thiab tsis kam mus rau ib puag ncig yam.

D. Nqi-zoo

Cov txiaj ntsig kev lag luam ntawm kev txhaj tshuaj molding rau kev tsim tsheb loj loj yog qhov tseem ceeb.Cov txheej txheem tso cai rau cov khoom ntim ntau nrog cov pov tseg tsawg, ua rau cov nqi qis dua ib feem thiab rov qab sai dua ntawm kev nqis peev.

IV.Txhim kho Automotive Manufacturing Efficiency

Ntxiv nrog rau nws qhov txiaj ntsig zoo, kev txhaj tshuaj molding kuj tseem txhawb nqa kev txhim kho tag nrho ntawm kev tsim tsheb.

A. Rapid Prototyping

Txhaj tshuaj molding pab kom ceev iteration thiab validation ntawm automotive ib feem tsim.Lub peev xwm prototyping sai no tso cai rau cov tuam txhab sim thiab kho cov qauv tsim ua ntej cog lus rau kev tsim khoom loj, txo cov sij hawm tsim kho thiab cov nqi.

B. Tsuas-hauv-Sijhawm Manufacturing

Qhov kev xav tau ntawm kev txhaj tshuaj molding txhawb nqa tsuas yog-hauv-lub sijhawm (JIT) kev tsim khoom.Txoj hauv kev no rau kev tswj cov khoom lag luam kom ntseeg tau tias cov khoom tsim tau raws li qhov xav tau, txo cov nqi khaws cia thiab txo qhov kev pheej hmoo ntawm kev ploj mus.

C. Tooling Innovations

Kev nce qib hauv kev tsim pwm thiab kev tsim cov txheej txheem tau ua rau kev txhaj tshuaj molding ntau dua rau kev siv tsheb.Cov cuab yeej niaj hnub tuaj yeem tsim cov khoom nrog ntau qhov nyuaj thiab qhov tseeb, thaum tseem txo lub sijhawm thiab tus nqi cuam tshuam nrog cov cuab yeej tsim khoom.

V. Kev lees paub zoo thiab kev tswj hwm kev ua raws cai

Kev ua tau zoo thiab kev ua raws cai yog tsis sib tham hauv kev lag luam tsheb, thiab kev txhaj tshuaj molding ua tau raws li cov kev xav tau ntawm lub taub hau.

A. Ua kom ruaj khov thiab ua haujlwm tau zoo

Kev soj ntsuam nruj thiab kev tswj xyuas qhov zoo yog qhov tseem ceeb rau kev txhaj tshuaj yas molding rau cov khoom siv tsheb.Cov txheej txheem no xyuas kom meej tias cov khoom ua tau raws li cov qauv siab xav tau rau kev ua haujlwm ntev thiab kev ua haujlwm hauv kev siv tsheb.

B. Ua raws li cov qauv kev lag luam

Ua raws li cov cai tswj kev lag luam tsheb thiab cov ntawv pov thawj rau kev nyab xeeb thiab kev ntseeg siab yog qhov yuav tsum tau ua.Cov txheej txheem txhaj tshuaj molding yog tsim los ua kom tau raws li cov qauv no, kom ntseeg tau tias cov khoom tsis yog tsuas yog ua haujlwm xwb tab sis kuj muaj kev nyab xeeb rau kev siv hauv tsheb.

VI.Sustainability thiab Environmental Impact

Hauv kev lag luam nce ntxiv tsom mus rau kev ruaj khov, kev cuam tshuam ib puag ncig ntawm cov txheej txheem tsim khoom yog qhov tseem ceeb.

A. Eco-Friendly Practices

Yas txhaj molding yog ib qho kev coj ua hauv eco-phooj ywg vim nws cov khoom siv rov ua dua tshiab thiab kev ruaj ntseg.Ntau cov yas siv hauv kev tsim tsheb tuaj yeem rov ua dua tshiab, txo cov khib nyiab thiab kev lag luam tag nrho ib puag ncig hneev taw.

B. Txo cov khoom pov tseg

Qhov ua tau zoo ntawm kev txhaj tshuaj molding txheej txheem hauv kev txo cov khoom seem yog lwm qhov txiaj ntsig zoo.Los ntawm kev tsim cov khoom siv nrog siab precision thiab tsawg tsawg, kev txhaj tshuaj molding pab txuag cov peev txheej thiab txo kev lag luam cuam tshuam rau ib puag ncig.

VII.Case Studies thiab Success Stories

Cov piv txwv tiag tiag hauv ntiaj teb tuaj yeem muab cov lus sib cav rau cov txiaj ntsig ntawm kev txhaj tshuaj yas hauv kev lag luam tsheb.

A. Qhia txog cov piv txwv tiag tiag hauv ntiaj teb

Cov ntaub ntawv tshawb fawb ntawm cov tuam txhab tsheb uas tau ua tiav kev siv cov yas txhaj tshuaj molding rau ntau yam khoom tuaj yeem muab cov kev nkag siab zoo.Cov piv txwv no tuaj yeem hais txog kev txhim kho hauv cov khoom lag luam, kev txuag nqi, thiab kev sib tw ua lag luam.

B. Txheeb xyuas qhov cuam tshuam

Kev soj ntsuam ntxaws ntxaws ntawm qhov cuam tshuam ntawm kev txhaj tshuaj molding ntawm cov tuam txhab no tuaj yeem nthuav tawm cov txiaj ntsig zoo ntawm cov txheej txheem tsim khoom no.Qhov no suav nrog tsis yog tsuas yog txuag nqi xwb tab sis kuj tseem txhim kho cov khoom zoo thiab cov neeg siv khoom txaus siab.

VIII.Yav tom ntej Trends thiab Innovations

Saib tom ntej, lub neej yav tom ntej ntawm kev tsim tsheb tsim tau tsim los ntawm kev sib txuas ntxiv ntawm cov thev naus laus zis thiab cov khoom siv.

A. Kev lag luam 4.0 Kev koom ua ke

Lub luag haujlwm ntawm automation, digitalization, thiab kev tsim khoom ntse hauv lub neej yav tom ntej ntawm kev tsim cov khoom siv tsheb yog qhov tseem ceeb.Kev txhaj tshuaj molding yog qhov chaw zoo kom tau txais txiaj ntsig los ntawm cov qauv no, nrog rau lub peev xwm rau kev ua kom zoo dua qub thiab raug los ntawm kev siv cov thev naus laus zis siab heev.

B. Cov khoom siv thiab cov thev naus laus zis siab heev

Cov kev hloov tshiab tshiab hauv kev txhim kho resin thiab kev tsim khoom ntxiv rau kev siv tsheb tau teeb tsa los txhim kho lub peev xwm ntawm kev txhaj tshuaj molding.Cov kev tsim kho tshiab no tuaj yeem ua rau kev tsim cov khoom siv tsheb ntau dua thiab muaj txiaj ntsig zoo.

Hauv kev xaus, qhov zoo ntawm cov yas txhaj tshuaj molding rau automotive Cheebtsam yog qhov tseeb.Cov txheej txheem muaj kev sib xyaw ua ke ntawm qhov tseeb, kev tsim qauv yooj yim, xaiv cov khoom siv, thiab kev siv nyiaj txiag uas yog qhov tseem ceeb rau kev ua kom tau raws li qhov xav tau ntawm kev lag luam tsheb.

Lub recapitulation ntawm cov zoo no underscores tus nqi uas txhaj tshuaj molding coj mus rau lub automotive manufacturing txheej txheem.Nws yog ib qho kev daws teeb meem uas tsis yog tsuas yog ua tau raws li cov kev xav tau tam sim no tab sis kuj hloov tau rau cov kev cov nyom thiab cov cib fim yav tom ntej.

Lub luag haujlwm tseem ceeb ntawm kev txhaj tshuaj molding hauv kev tsav tsheb ua haujlwm zoo, kev ua haujlwm zoo, thiab kev tsim kho tshiab hauv kev lag luam tsheb tsis tuaj yeem overstated.Nws yog ib qho txheej txheem uas tseem ceeb rau kev lag luam muaj peev xwm tsim cov tsheb zoo uas muaj kev nyab xeeb, txhim khu kev qha, thiab cov nqi sib tw.

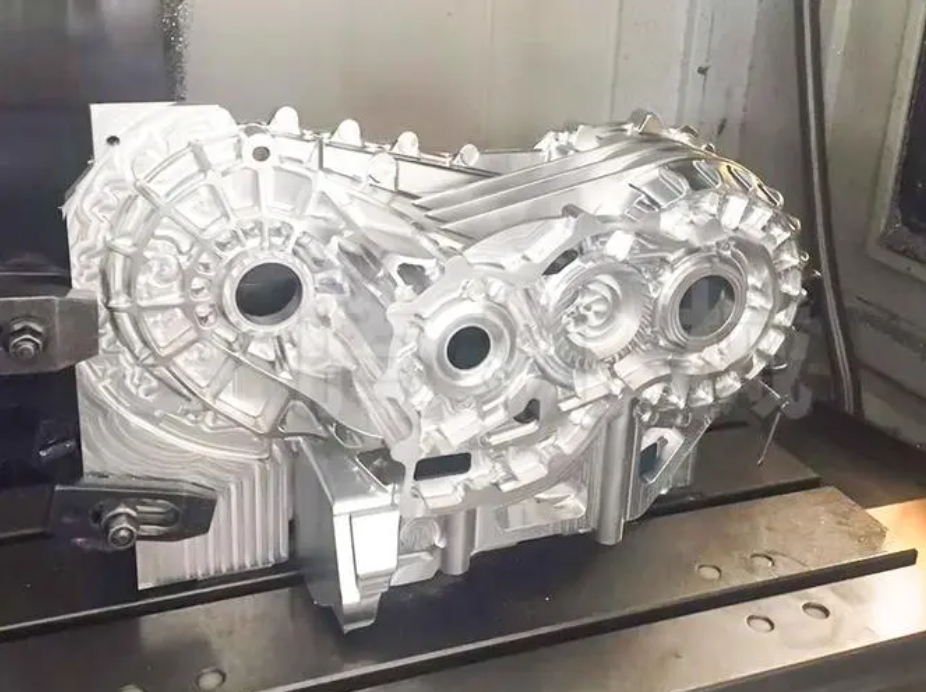

AtFoshan Hongshuo Pwm Co., Ltd.,peb nkag siab txog qhov tseem ceeb ntawm qhov tseeb thiab qhov tseeb hauv kev tsim pwm.Peb muaj peev xwm tsim tau 200 teeb ntawm precision pwm ib lub hlis thiab muaj peev xwm txhaj 200,000 rau 500,000 yas qhov chaw.Cov lej no qhia txog peb txoj kev mob siab rau kev tsim khoom raws sijhawm thiab ua haujlwm tau zoo, ua kom peb cov neeg siv khoom tuaj yeem tso siab rau peb kom ua tau raws li lawv cov kev xav tau.

Peb cov pwm tau raug xa tawm mus rau ntau tshaj 20 lub teb chaws thoob ntiaj teb, ua pov thawj rau peb txoj kev mob siab thiab kev ua haujlwm zoo tshaj plaws.Peb lub ntiaj teb muaj zog muaj xws li kev lag luam xws li Russia, Canada, Egypt, Israel, Spain thiab Poland.Qhov kev nthuav dav no qhia txog peb txoj kev cog lus los muab kev pabcuam tshwj xeeb thiab kev pabcuam zoo rau peb cov neeg siv khoom thoob ntiaj teb.

Xav tias dawb rautiv tauj peb thaum twg los tau!Peb nyob ntawm no los pab thiab xav hnov los ntawm koj.

Chaw Nyob: Plaub Ntug, No. 32, Xinghua East Road, Ronggui Bianjiao Pawg Neeg Zej Zog, Shunde District, Foshan City

Xov tooj: +8618024929981

Whatsapp: 8618029248846

xa ntawv:molly@m-stephome.com

Sales Executive

Post lub sij hawm: May-28-2024