Yav dhau los Moulds ua thiab cov khoom pub dawb tsim

Peb Cov Kev Pabcuam Yas Txhaj Molding

Siv CNC Machining kom xa cov txiaj ntsig zoo dua

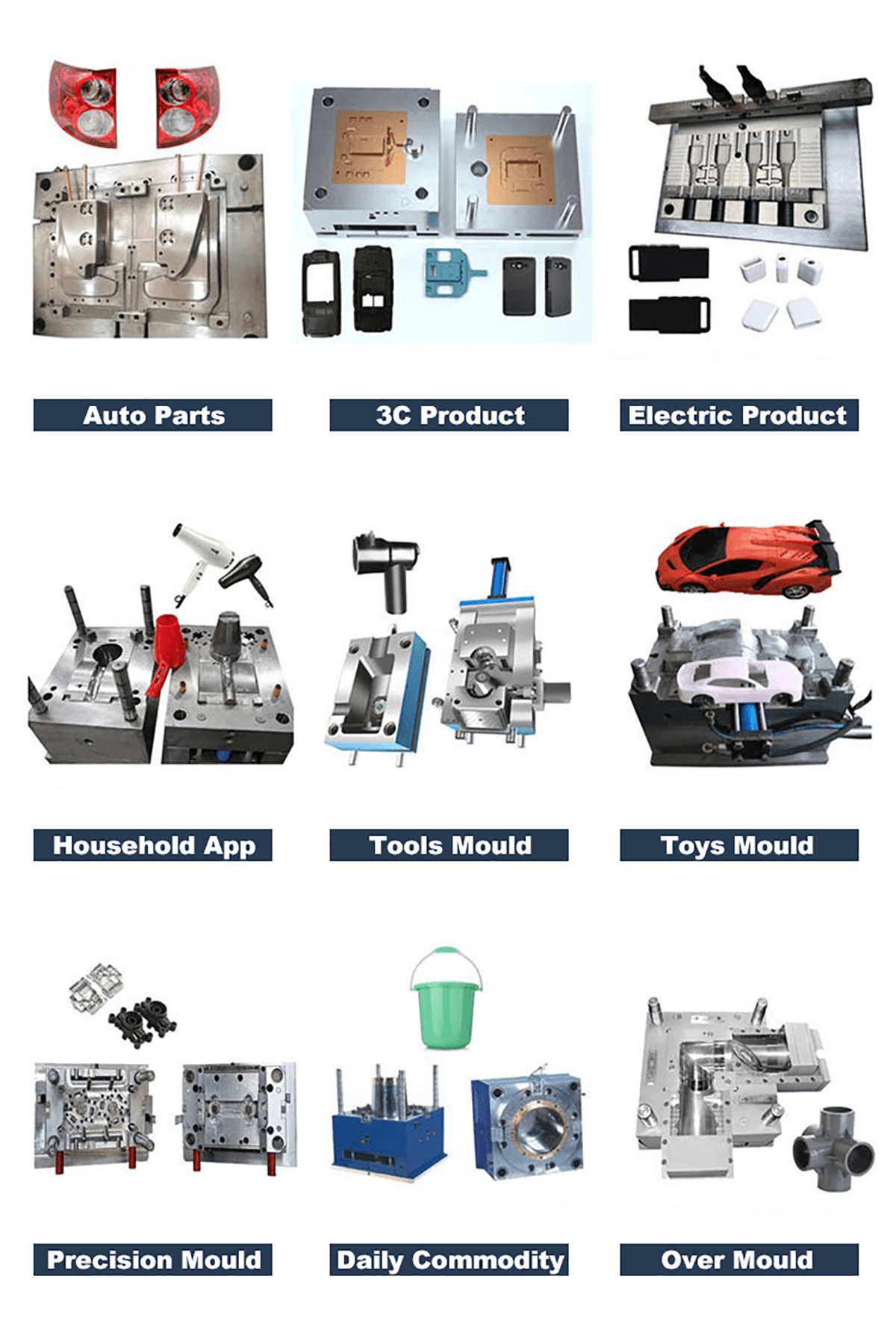

Hauv kev tsim khoom, cov txheej txheem tsim cov yas txhaj tshuaj pwm plays lub luag haujlwm tseem ceeb.Cov pwm no yog ib qho tseem ceeb rau kev tsim khoom ntawm ntau yam khoom, nrog rau cov khoom siv hauv tsev, cov khoom ua si, 3C cov khoom siv hluav taws xob, cov khoom siv pib thiab cov khoom siv niaj hnub, thiab lwm yam.Nrog peb cov kev paub dhau los thiab kev txawj ntse, peb tau ua tiav cov txuj ci ntawm kev tsim pwm rau cov qauv kev lag luam siab tshaj plaws.Tsis tas li ntawd, peb ntiav CNC machining, ib qho kev tsim khoom tshiab uas lav tau sai thiab meej ntawm kev txhaj tshuaj molded qhov chaw.

Hais txog peb:

Peb lub tuam txhab muaj cov ntaub ntawv zoo tshaj plaws hauv kev tsim pwm.Nrog ntau xyoo ntawm kev lag luam kev lag luam, peb tau ua tiav ntau hom pwm kom tau raws li qhov xav tau ntawm kev lag luam sib txawv.Los ntawm cov khoom siv hauv tsev mus rau cov khoom siv hluav taws xob, peb tsim ntau yam khoom los xyuas kom cov neeg siv khoom txaus siab txhua lub sijhawm.Peb txoj kev mob siab rau kev ua tau zoo thiab kev mloog zoo rau kev nthuav dav tau tsim peb lub koob npe nrov raws li kev ntseeg siab yas txhaj tshuaj pwm tsum.

Kawm txog kev txhaj tshuaj molds:

Yas txhaj tshuaj molding yog ib txoj kev tsim khoom siv dav siv uas koom nrog kev txhaj tshuaj molten rau hauv cov pwm kev cai.Cov txheej txheem no tuaj yeem tsim cov duab nyuaj thiab cov qauv uas yuav tsis yooj yim rau kev ua tiav.Cov khoom siv yas solidifies hauv pwm, noj cov duab thiab tsim ntawm pwm kab noj hniav.Thaum txias thiab hardened, cov molded qhov chaw yog ejected, npaj rau ntxiv ua los yog sib dhos.

Txhaj Mould CNC Machining:

Hauv peb lub tuam txhab, peb tau ua CNC machining qhov tseem ceeb ntawm peb cov txheej txheem tsim khoom.CNC (Computer Numerical Control) machining yog cov txheej txheem uas siv lub tshuab computer tswj kom ua haujlwm precision machinery.Hauv kev txhaj tshuaj yas pwm, CNC machining txhim kho efficiency thiab precision, ua rau cov khoom zoo.

Muaj ntau qhov zoo rau kev siv CNC machining hauv cov yas txhaj tshuaj pwm ntau lawm.Ua ntej, nws txo qis lub sijhawm tsim khoom tsim nyog rau txhua pwm.Lub tshuab computer tswj tau ua kom nrawm, meej machining kom ua tiav qhov project sai.Txo cov sij hawm txhuas yog qhov txiaj ntsig tseem ceeb rau cov lag luam vim nws txhais ncaj qha rau hauv cov voj voog tsim khoom luv luv thiab lub sijhawm ua lag luam sai dua.

Thib ob, CNC machining kom paub meej tshwj xeeb hauv kev tsim cov yas txhaj tshuaj pwm.Automated tswj tshuab muaj peev xwm tsim cov qauv tsim nrog qhov tseeb tshaj plaws.Qhov no theem ntawm precision xyuas kom meej tias cov khoom kawg ncaj ncees replicates lub hom phiaj pwm, ua tau raws li qhov tseeb specifications thiab yuav tsum tau ntawm cov neeg muas zaub.

Tsis tas li ntawd, CNC machining enables repeatability nyob rau hauv zus tau tej cov yas txhaj pwm.Lub khoos phis tawj tswj xyuas kom ntseeg tau tias txhua cov pwm tsim tawm yog qhov tseeb ntawm tus qauv tsim.Qhov kev sib xws no yog qhov tseem ceeb, tshwj xeeb tshaj yog thaum tsim cov khoom lag luam ntawm qhov ntsuas lossis tswj qhov sib xws ntawm cov khoom sib txawv.

nyob rau hauv xaus:

peb lub tuam txhab muaj kev txaus siab heev hauv kev muab cov kev pabcuam dav dav rau kev txhaj tshuaj pwm.Peb muaj cov ntaub ntawv pov thawj ntawm kev muab cov pwm saum toj kawg nkaus rau ntau qhov chaw xws li cov khoom siv hauv tsev, cov khoom ua si, 3C cov khoom siv hluav taws xob, qhov chaw pib thiab cov khoom siv niaj hnub.Peb siv CNC machining ntxiv txhim kho peb lub peev xwm los tsim pwm sai thiab raug.Cov txheej txheem tsim tshwj xeeb no ua kom peb cov neeg siv khoom sai sai tau txais cov khoom zoo meej ntawm cov khoom yas uas lawv xav tau.Txawm hais tias koj xav tau cov pwm yooj yim lossis cov qauv tsim, peb tuaj yeem muab cov kev daws teeb meem sai thiab txaus siab rau koj cov kev xav tau ntawm cov yas txhaj tshuaj molding.

Product Detail

| Qhov Chaw Keeb Kwm | Tuam Tshoj |

| Hom Lub Npe | HSLD / Customized |

| Hloov hom | Ntxuam Yas Txhaj Pwm |

| Khoom siv | CNC, EDM txiav tawm tshuab, Yas Machinery, thiab lwm yam |

| Khoom siv | Hlau: AP20/718/738/NAK80/S136 Yas: ABS / PP / PS / PE / PVC / PA6 / PA66 / POM |

| Pwm Lub Neej | 300000 ~ 500000 txhaj tshuaj |

| Tus khiav | Kub khiav los yog txias khiav |

| Hom rooj vag | Ntug/Pin point/Sub/Side Gate |

| Kev kho saum npoo | Matte, Polished, Daim iav polished, kev ntxhib los mos, painting, thiab lwm yam. |

| Pwm Cavity | Ib leeg lossis ntau kab noj hniav |

| Ua siab ntev | 0.01mm-0.02 hli |

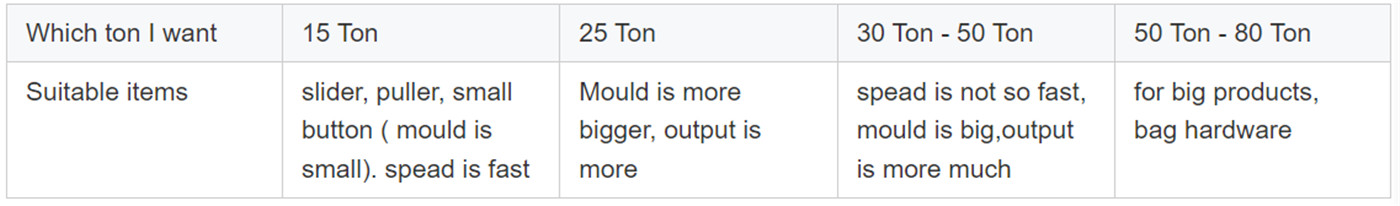

| Txhaj Tshuab | 80T-1200 T |

| Ua siab ntev | ± 0.01 hli |

| Dawb qauv | muaj |

| Qhov zoo | one stop solution/free design |

| Daim ntawv thov teb | Cov khoom siv hluav taws xob, cov khoom zoo nkauj, cov khoom siv kho mob, cov khoom siv hauv tsev, Cov khoom siv pib, thiab lwm yam |

Lub Hoobkas Paub meej

Ntau Moulds

Kev xa khoom

Kev ntim tshwj xeeb rau koj: rooj ntoo nrog zaj duab xis

1. Txhawm rau kom zoo dua kev nyab xeeb ntawm koj cov khoom, kev tshaj lij.

2. Zoo rau ib puag ncig, kev pabcuam ntim khoom yooj yim thiab ua haujlwm tau zoo.

FAQ

HSLD: Yog lawm, feem ntau cov khoom seem rau tuag casting pwm peb muaj pwm ntxig, pwm ncej, qhov rais tub ntxhais, txav tub ntxhais, lub taub hau ntawm nozzle.Koj tuaj yeem tshawb xyuas thiab qhia txog yam khoom seem uas koj xav tau.

HSLD: Peb cov pwm ntxig yog ua los ntawm DAC.

HSLD: Peb lub hauv paus txav yog ua los ntawm FDAC.

HSLD: Yog.

HSLD: Cov khoom sib txawv muaj qhov sib txawv, feem ntau ntawm 0.01-0.02mm